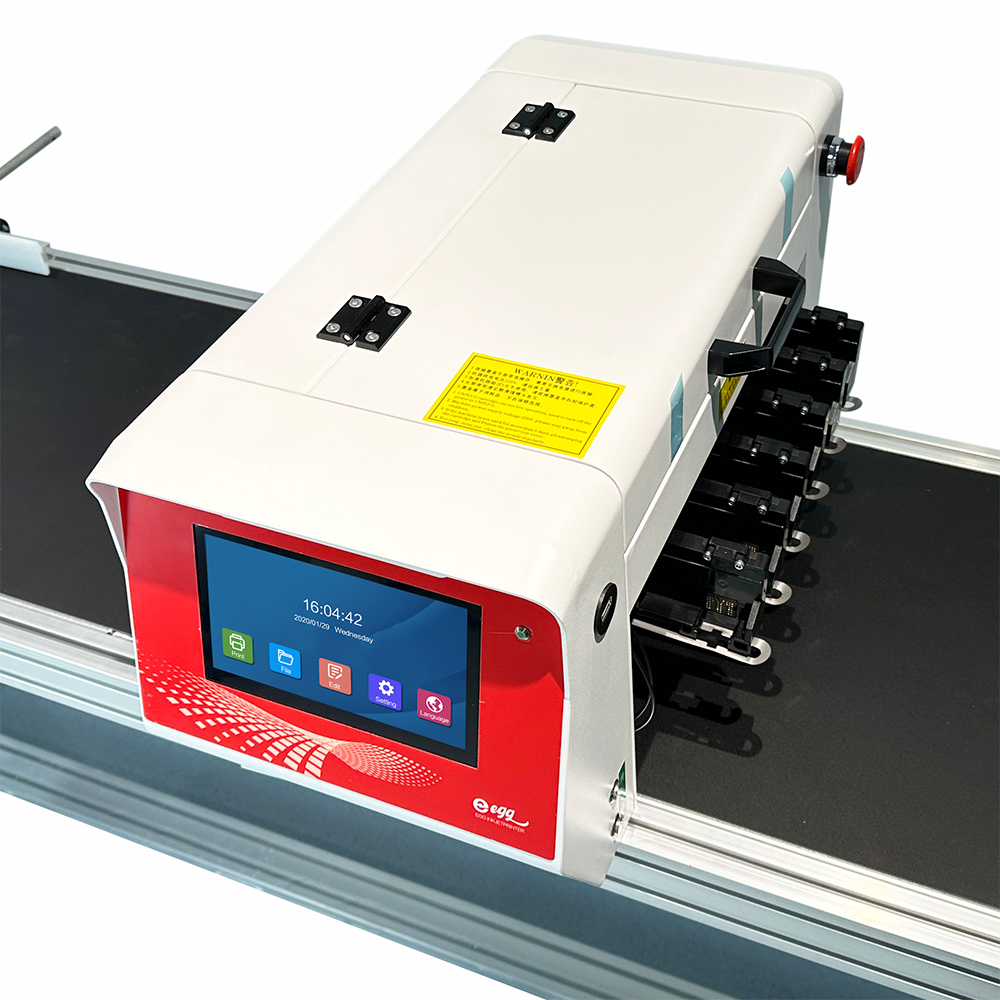

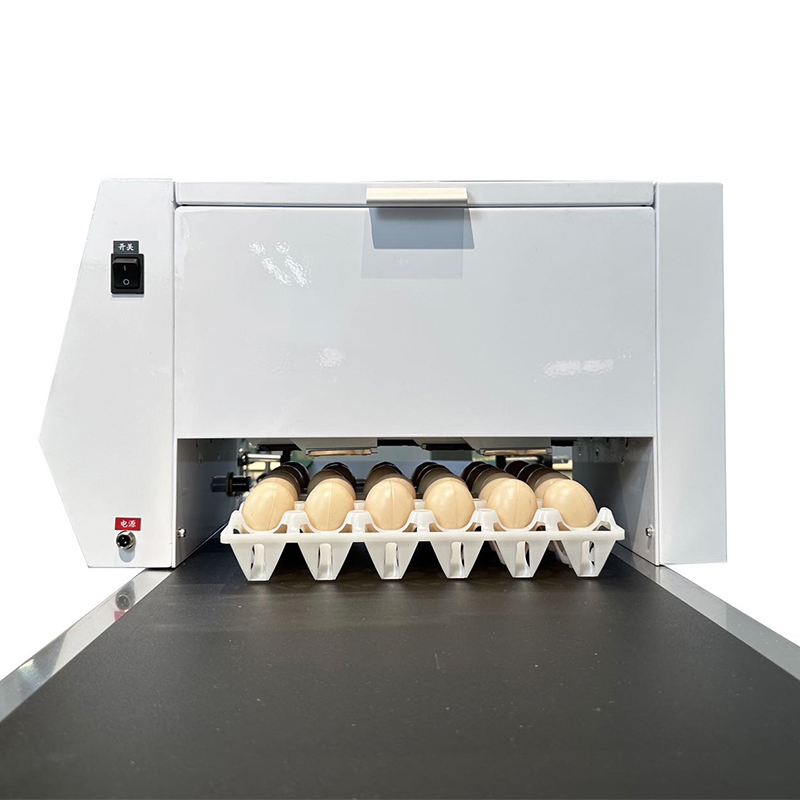

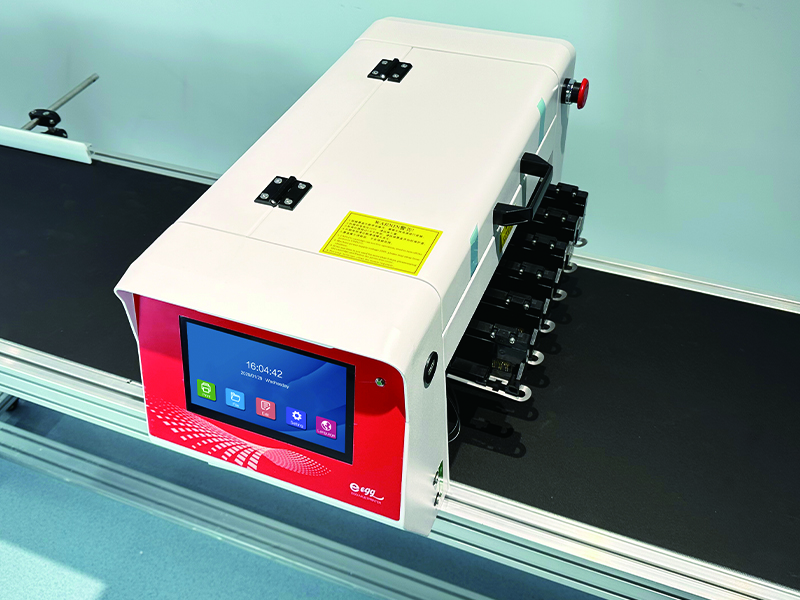

High Speed Eggs Expiry Date Printing Printer Machine

High Speed Eggs Expiry Date Printing Printer Machine

Egg printers, as core equipment for standardized production in the egg industry, have deeply penetrated the entire industry chain, including farms, egg processing plants, brand distributors, and export companies.

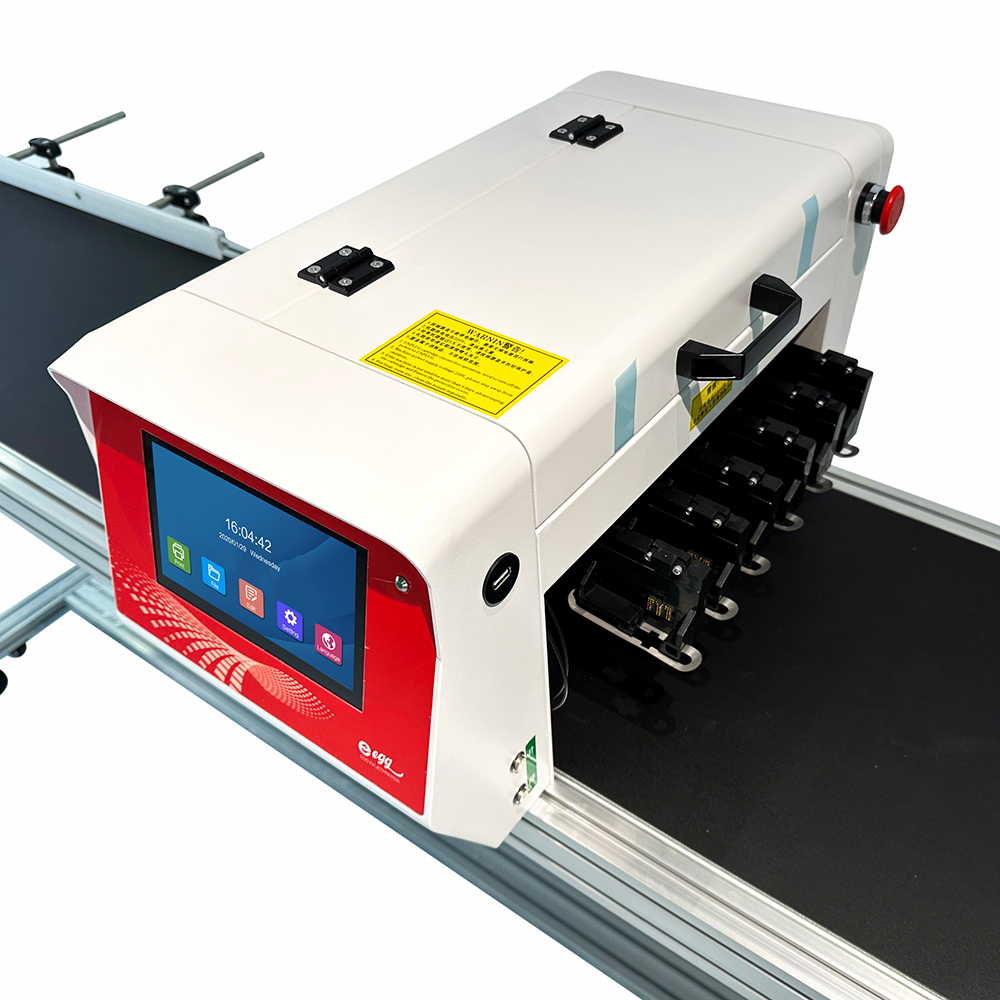

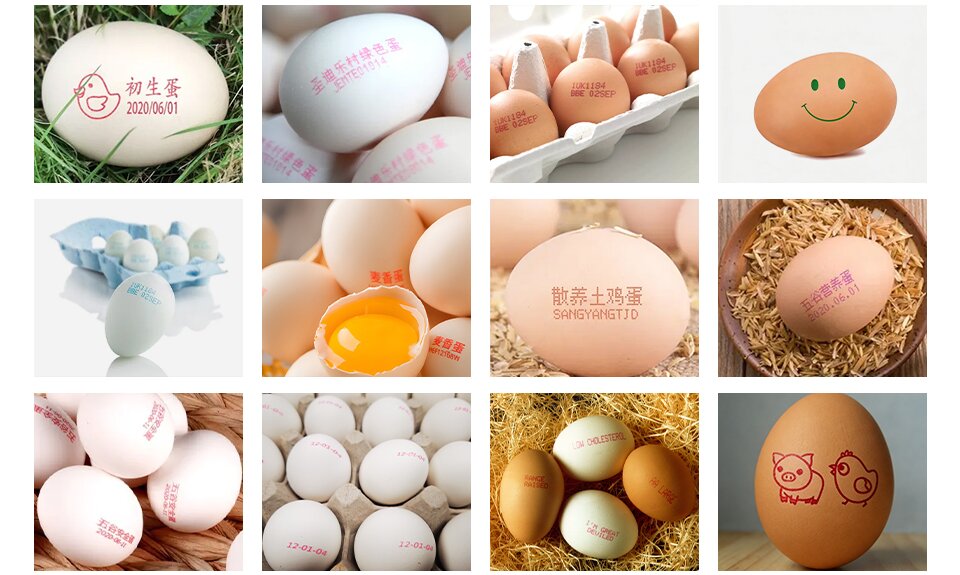

At the farm level, the equipment can directly and accurately print key information such as production date, origin code, and quarantine certificate on the surface of fresh eggs, building a "one item, one code" traceability system from the source and strengthening the first line of defense for food safety.

In the processing stage, the printer enables batch simultaneous printing of entire trays of eggs, eliminating the need for additional processing steps, significantly improving production efficiency, helping companies achieve large-scale and standardized production upgrades, and meeting the compliance requirements for egg labeling in domestic and international markets.

Email: [email protected]

WA: +8615524171453

Features

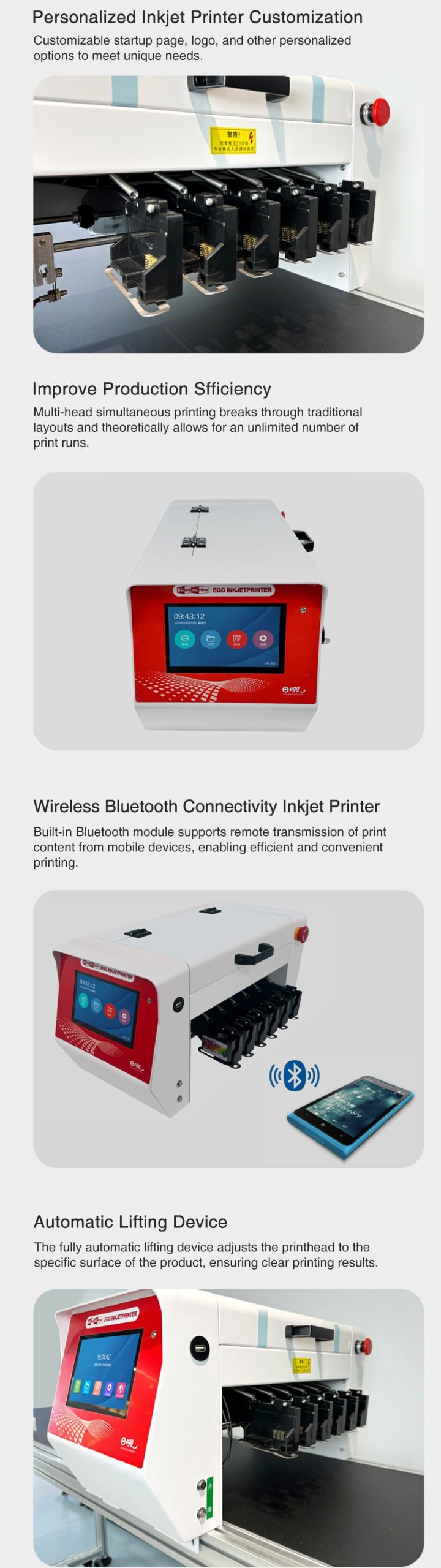

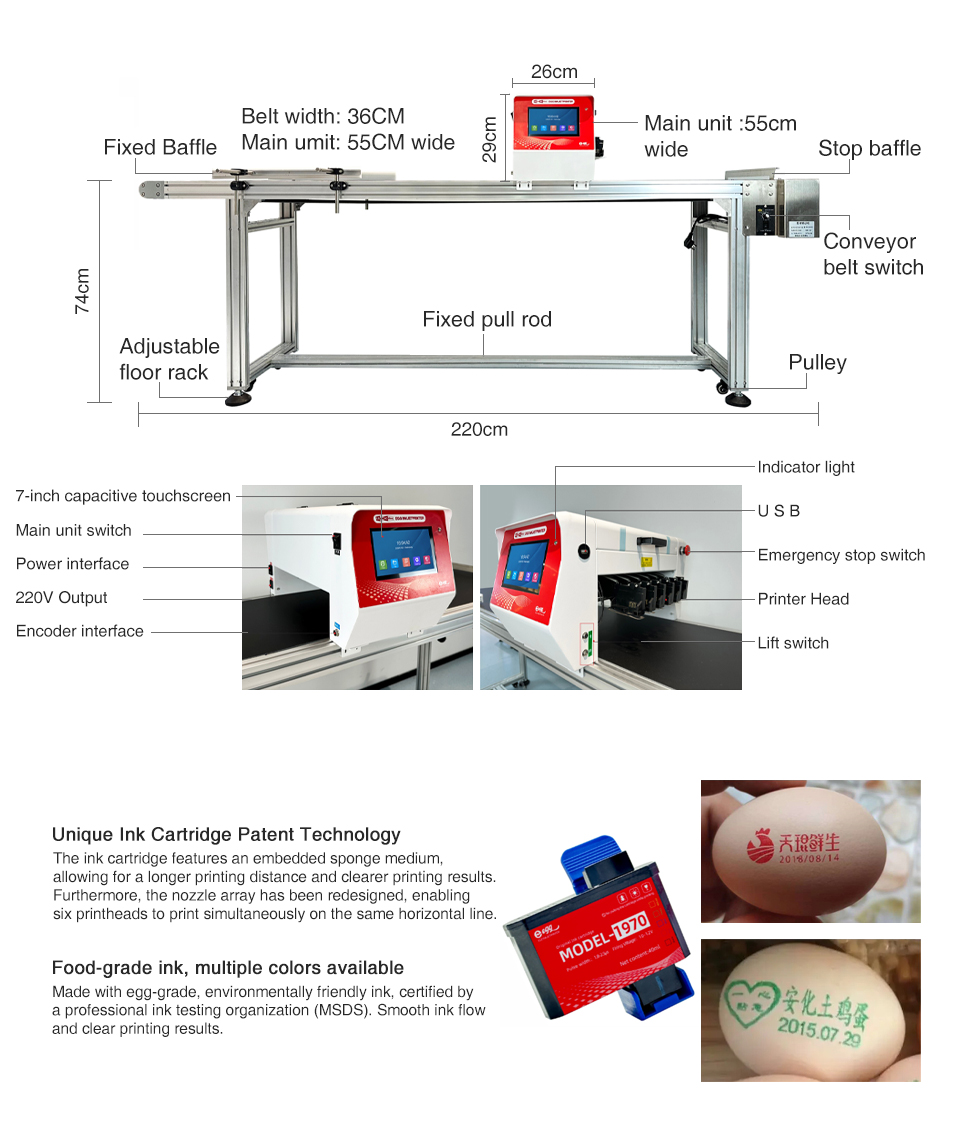

Employing Fiber Optic Sensing Equipment

The six-head egg inkjet printer upgrades traditional photoelectric sensing equipment to fiber optic sensors, resulting in greater sensitivity and flexibility.

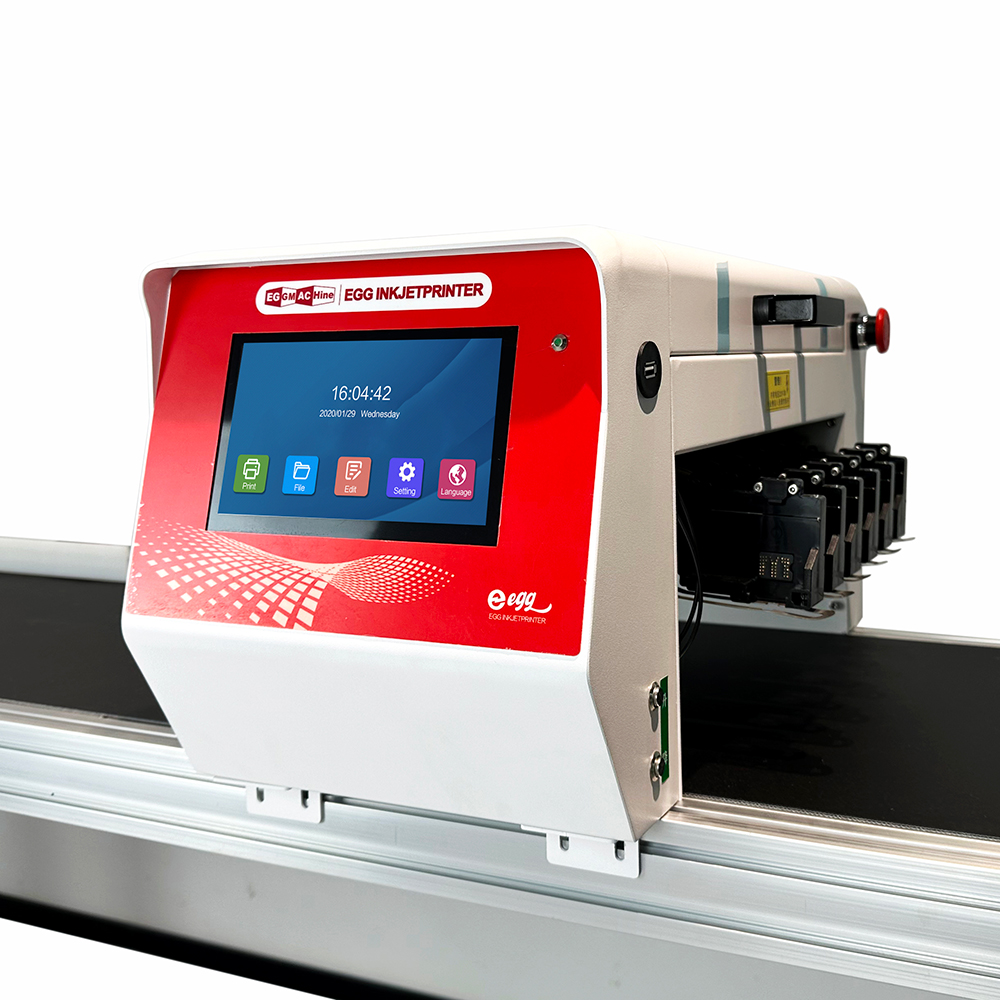

Six Printheads Print Simultaneously

The new six-head egg inkjet printer uses printheads to print simultaneously on the same horizontal line, eliminating the traditional row/column layout and instead focusing on the number of prints. This significantly increases work efficiency, and theoretically, allows for an unlimited number of prints.

Unique Spring-Loaded Swing Arm Design

The spring-loaded swing arm design provides better stability and printing quality for the object being printed.

Product Detail

Copyright © 2025 Design by Shenyang Faith Technology Co., Ltd.. All rights reserved.

Send Inquiry

Please leave the message you want to inquiry. We will reply you as soon as possible within 24 hours.