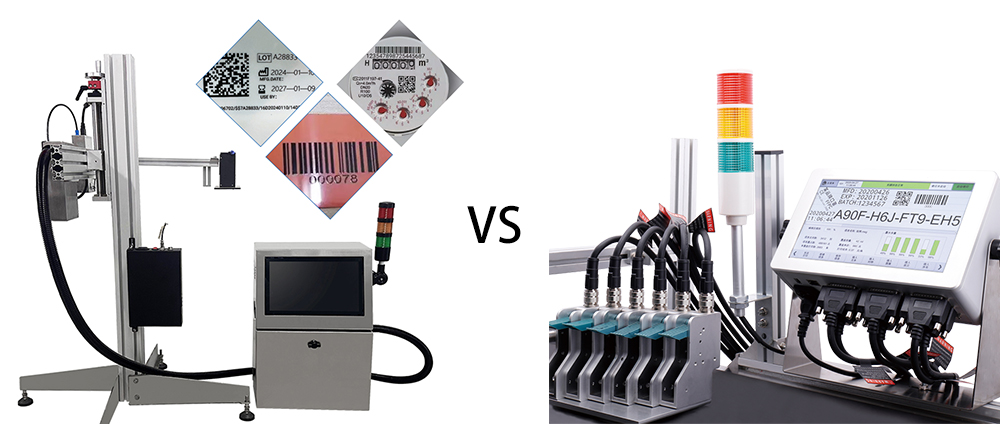

Why PIJ Stitching Printing is Better Than TIJ Printing

News detail

Why PIJ Stitching Printing is Better Than TIJ Printing

PIJ (Piezoelectric Inkjet) is superior to TIJ (Thermal Inkjet) in terms of splicing printing effects. The core reason lies in the differences in technical principles, ink drop control and equipment characteristics, which are specifically reflected in the following aspects:

1. Ink drop control accuracy: Piezoelectric technology is more accurate

PIJ technology: By deforming and squeezing ink through piezoelectric crystals, the ink drop size (minimum 2-4pl) and injection position can be accurately controlled, and the ink drop edge is clear and the positioning error is small. When splicing printing, the ink droplets in the overlapping area of multiple nozzles are evenly distributed to avoid color difference, stripes or uneven ink volume.

TIJ technology: Relying on heating elements to generate bubbles to push ink droplets, the ink drop size is affected by temperature fluctuations (usually 10-30pl), and the injection stability is poor. When splicing, it is easy to cause the overlapping area to have different shades of color due to inconsistent ink drop volume, and obvious splicing marks will appear.

2. Ink compatibility: PIJ supports more high-performance inks

PIJ: Compatible with high-viscosity inks such as pigment inks and UV inks, with high color saturation, strong light and water resistance, fine ink particles, and a wider printing color gamut. The color consistency of different areas during splicing is better, especially suitable for outdoor advertising, industrial signs and other scenes with high durability requirements.

TIJ: Dye inks are mostly used (a few high-end models support pigment inks). The ink viscosity is low and easy to diffuse. Color smudges may appear in overlapping areas during splicing, and the weather resistance is poor. It is easy to fade after long-term use, affecting the overall effect.

3. Nozzle life and stability: PIJ is more suitable for long-term splicing operations

PIJ nozzles: No heating element loss, life span can reach tens of thousands of hours, the nozzle state is stable under long-term high-frequency use, and the jetting performance of each nozzle is highly consistent during splicing printing, reducing the problems of ink breakage and color cast caused by nozzle aging.

TIJ nozzle: The heating element is prone to wear and tear due to frequent operation (usually thousands of hours of life). Long-term splicing printing may cause nozzle performance degradation, resulting in different ink output in different areas and obvious defects at the splicing.

4. Resolution and detail performance: PIJ supports higher precision

PIJ: Micro-piezoelectric technology can achieve a high resolution of more than 1200dpi, the ink droplets are arranged more closely, and the edge transition is natural during splicing. Even in large-format printing, the sharpness of text and images can be maintained, and the overlapping area is almost invisible.

TIJ: The mainstream resolution is mostly 600-1200dpi, and the ink drop spacing is large. If the resolution is insufficient during splicing, pixelation or jagged edges are likely to appear in the overlapping area, affecting the overall image quality.

5. Splicing synchronization: PIJ drive response is more consistent

PIJ: The electrical signal drive response speed of the piezoelectric crystal is fast (nanosecond level), and the jet rhythm synchronization is high when multiple nozzles are spliced, avoiding ink drop dislocation caused by delay, which is especially suitable for high-speed printing scenarios.

TIJ: There is a delay in the heat conduction of the heating element. When multiple nozzles work together, the heating cycle may be asynchronous, resulting in uneven ink droplet distribution at the splicing point, and horizontal or vertical stripes.

VI. Maintenance cost and reliability: PIJ is easier to maintain stable effects

PIJ equipment: There is no need to frequently replace the nozzle, the maintenance cost is low, and the ink channel is not easy to precipitate due to heating. The consistency of the splicing effect is easier to maintain after long-term use.

TIJ equipment: The nozzle needs to be replaced regularly, and the heating element is easily blocked or corroded by ink impurities. Improper maintenance will directly affect the splicing accuracy and cause effect fluctuations.

Summary

PIJ technology, with the advantages of "high-precision ink drop control + high-performance ink compatibility + long-life nozzle", can achieve more uniform color transitions, more delicate details and more stable long-term effects when splicing printing. It is especially suitable for large-format advertising, industrial logos, packaging printing and other scenes with high splicing accuracy requirements. However, TIJ technology is more used in consumer-grade printers due to its low cost and simple structure. It is difficult to match the performance of PIJ in the field of professional splicing printing.

Copyright © 2025 Design by Shenyang Faith Technology Co., Ltd.. All rights reserved.

Send Inquiry

Please leave the message you want to inquiry. We will reply you as soon as possible within 24 hours.